|

| front window |

|

| side windows |

For comparison, you can see photos of the original room here.

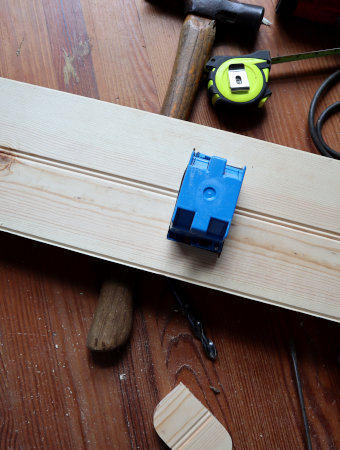

Then there's the floor, which is in pretty bad shape.

If I'm remembering correctly, this is actually the sub-floor, which was probably intended to be covered. I would love to put a hardwood floor on top of it. Even wall-to-wall carpet would help. But for now, we don't have the funds to do anything with it. So I need a temporary solution.

Another problem, is this . . .

The house originally had two back-to-back fireplaces, one in the living room and one in this bedroom. Unfortunately, the mortar in the original chimney was soft enough to poke your finger through, so everything was torn out. You can see the interesting innards of a dual chimney here.

It would also be nice to do something with this closet.

It's about 6-feet long and very shallow, just 17.5" deep, which is barely wide enough for clothes hangers. The shelves are on one side only. The door opening is 23 in. by 6 ft, so it's awkward to utilize the space. Making it deeper would mean building it out into the room; an idea we've discussed. I think an easier solution would be to tear out the door and wall to the left and hang a pair of by-pass doors. I keep off-season clothing in there, but mostly it's for storage.

Even in opting for the simplest solutions, the ability to actually do anything isn't imminent. In discussing what needs to be done, Dan said he'd be able to work around the loom, which gave me the go-ahead. The room will be finished eventually, but for now, I want to abandon the storage facility decor and make the room functional. I want to use my large loom again.

For now, I decided to cover the floor with an area rug and there it is. This is actually my old dining room rug, which I replaced with a new, cleaner one. The loom is in the middle of the room, with space to walk around it and get to the windows. There's enough room to scoot it over if needed.

I still need to attach the texsolv cords, which is called "tying up." This connects all the moving parts (countermarch, shafts, lamms, and treadles).

It's a project in itself because everything must be even and level.

Both Dan and I are pleased to see the loom assembled again. It certainly looks better than piles of boxes! I'd like to weave rugs, draperies, and yardage on this loom and use the table loom for smaller projects such as hand towels, table runners, scarves, etc. (My next planned project for the table loom is a small t-shirt yarn bathroom rug.)

After the windows are finished off, I can paint, which always freshens up a room. In the meantime, though, we can at least enjoy this room once again.